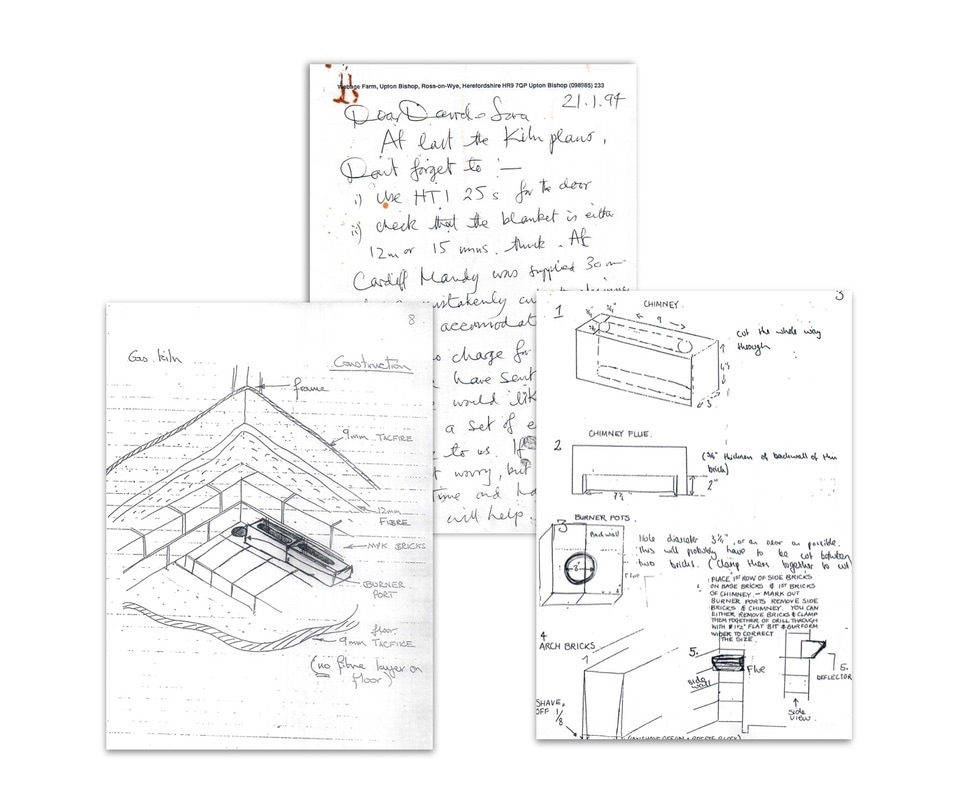

The plans in themselves were helpful but lacked an overall picture of what the kiln would look like. Thankfully there were enough intact arch bricks and the entire wicket (though I've subsequently had to remake this from fresh HTI26's) to enable me to piece together with the help of the plans a structure and plan. The bricks, plan and burners (yet to be fully tested) cost me £200. I have had to buy an additional 80 HTI26 refractory bricks, ceramic paper, ceramic blanket and Supalux board and have also had to commission the frame from a local metalworks near Stroud. This would make the total cost of materials, original bricks and plans bro £800. Building the kiln was, however, frustrated by the need for it to have a home to live in. There being no other structure to house it the first teas was to build a shed.

8 Comments

Maria

3/25/2019 05:25:39 am

Hey there! Was there ever a part 2? I have several boxes of bricks myself that I’m trying to figure out what to do with. Part 1 here is an inspiration. :)

Reply

Pete

10/26/2019 04:38:40 am

Just wondering what you have done for a door or do you brick it up?

Reply

Ratan Biswas

11/14/2019 07:51:06 am

Just amezing

Reply

Gareth Greenwood

10/1/2020 06:46:37 am

Hi Tom, I pot in Beper, Derbyshire (the original home of the now Denby Pottery down the road). I am in the process of moving from a wood firing to propane gas and building a 20 cubic foot kiln to work with.

Reply

10/30/2020 03:47:08 am

Hi I have just seen your kiln build and was wondering about your shed.

Reply

Jesus Alvarez

8/6/2022 05:12:43 pm

I'm interested to know what size is your kiln

Reply

Leave a Reply. |

AuthorTom K Jackson Archives

January 2017

|

|

TKJ Ceramics Ltd

A private limited company incorporated under the Companies Act 2006 and registered in England and Wales; company number: 10496837 |

RSS Feed

RSS Feed